Introduction: Beyond the Drone Flight: What Matters is the Usable Report

Solar panels are a long-term investment, but their performance can decline annually due to hidden defects. A drone inspection is a fast and safe way to map the health of your installation. However, raw thermal images or a long list of photos are often insufficient for a manager or owner.

At Droneview.be, we know: the true value of an inspection is not in the flight, but in the structured report you receive. We ensure that every hotspot and defect is translated into a direct actionable step.

Step 1: Data Collection – What the Drone Sees

Our specialized drones (equipped with cameras such as the DJI Zenmuse XT2) collect two crucial data streams simultaneously:

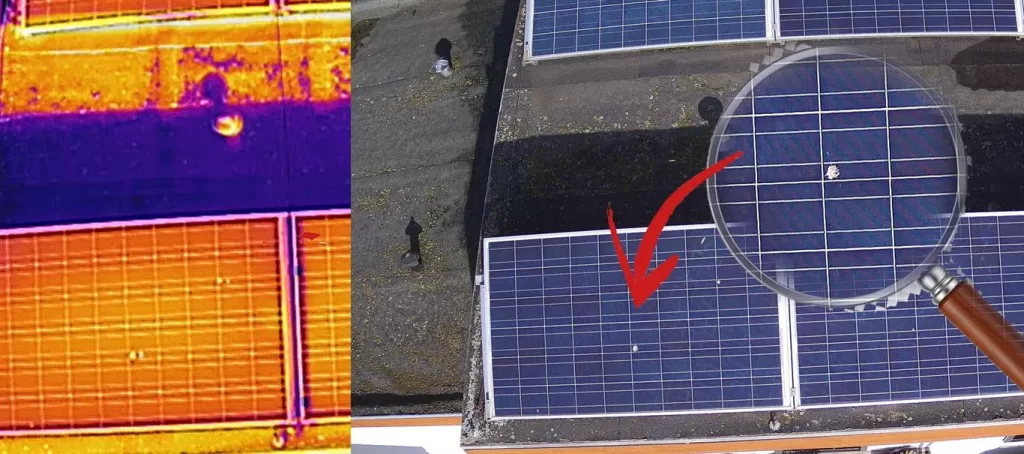

- Thermal (IR) Images: These record heat differences. A defective solar cell, a broken bypass diode, or a poor connection emits heat and appears as a bright ‘hotspot’ in the image. This is the primary source of defect detection.

- Visual (RGB) Images: These 4K images provide the visual context. They are essential for identifying physical damage (such as cracks) or contamination (such as bird droppings or leaves).

In addition, each image is provided with accurate GPS coordinates (Geotagging). This is the key to quickly locating and repairing defects on your large installation.

Step 2: The Analysis – From Hotspot to Defect

Once the flight is completed, the crucial analysis phase follows. Here we convert thermal anomalies into actionable findings. The most common defects we identify are:

Step 3: The Structured Report – What the Client Really Needs

The final report you receive from Droneview.be is built around one principle: Make it easy to repair.

1. Management Summary

A concise, non-technical conclusion on the first page. This includes:

- The total number of identified (critical) defects.

- The key recommendation (e.g., immediate repair of critical hotspots).

2. The Orthomosaic Overview Map

We provide a complete, geotagged orthomosaic map of your solar park. On this digital map, all individual defects (hotspots) are marked with clickable labels. Technicians can use these coordinates to navigate directly to the correct string and panel.

3. The Detailed Defect List

All identified defects are compiled in a structured table, including:

4. Reference Images

For each critical defect, we provide a set of two images: the thermal image showing the issue, and the visual (RGB) image showing the context and exact location.

Conclusion: From Inspection to Action

A professional drone inspection is only half of the solution. By delivering the data in a structured and action-oriented way, Droneview.be enables you to carry out costly repairs efficiently, minimize downtime, and maximize the return from your solar panels.

Ready to Turn Data into Return?

Our expertise goes beyond flying. We provide you with insight, not just images.

Do you want to know how much of your energy production is being lost unnoticed?

Contact Droneview.be today for a complete thermal and visual inspection offer, including our structured, action-oriented final report.